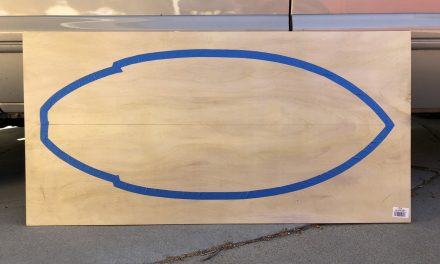

No, your vision isn’t blurred. You’re seeing a step of progress in the lengthy battle to achieve an appropriate finish for a Seawood skimboard.

The surface on the left is (hopefully) midway through the challenge. The one on the right is (even more hopefully) much closer to being done. To this point, there have been at least 15 bouts of sanding and varnishing. That’s right, 15+.

The problem is that sanding leaves a rough surface, even if the irregularities are only small scratches from the sharp paper. Then, the brushed on varnish is thick enough to fill the lines, but it usually fails to level out and shows lumpy lines from the brush strokes. Spray on varnish can give a more even coating but often lacks the bright gloss glow we want for a showroom finish.

Thus, the struggle continues until it all comes together for a completed project. We will post another photo when the deed is done so the journey will be totally documented for your viewing pleasure.